Free barcode generator

Create barcodes, vector (PDF, AI, EPS) or image (PNG, JPG)

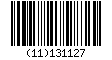

EAN-8 barcode

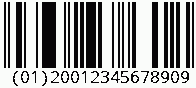

EAN-13 barcode

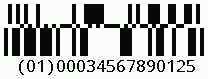

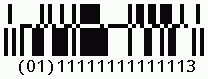

EAN-14 (UCC-14/GTIN-14) barcode

EAN-18 (SSCC-18) barcode

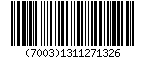

EAN-128 (GS1-128) barcode

UPC-A barcode

UPC-E barcode

DataBar (RSS-14)

DataBar Stacked (RSS-14 Stacked)

DataBar Limited (RSS Limited)

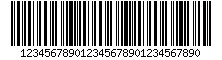

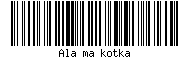

Code-128 barcode

Code-93 barcode

Code-39 barcode

Code-32 barcode

Code-11 barcode

Matrix 2 of 5 barcode

Standard 2 of 5 barcode

Interleaved 2 of 5 barcode

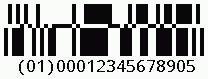

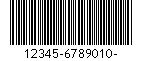

ITF-14 barcode

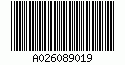

Identcode barcode

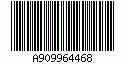

Leitcode barcode

Codabar barcode

Codabar Rationalized barcode

MSI Plessey barcode

Pharmacode One Track barcode

Pharmacode Two Track barcode

Postnet barcode

Planet barcode

Royalmail (RM4SCC) barcode

Aztec code

DataMatrix code

QR code

PDF417 code

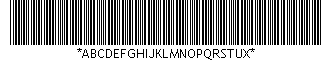

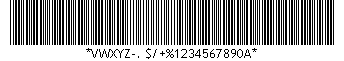

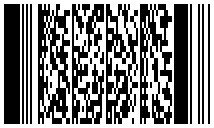

Code-16K

What is the bar code

Barcode is a graphical presentation of information.

The information is encoded with dark and light stripes, determined by symbolism-specific code.

Barcode is designed for e-readers, additionally usually under the code there is placed the text representation of what was contained in the code.

It is designed to allow manual entry of code where the reader will not be able to read the information.

The use of codes

Barcode found the widest application in trade. The main use of the bar code is the automatic identification of products, which allows much faster, for example customer service at cash registers.

Nowadays it is practically impossible to find in store merchandise that hasn't got a bar code assigned.

If the shop gets merchandise that does not have an official barcode, the shop assigns custom barcode to it.

Even companies associated with the transport couldn't resist the popularity of barcode: every parcel, pallet is labeled with a barcode.

Barcode reproduction

A key element that determines whether barcode fulfills its primary task is print quality.

The print quality is dependent on the nature of the ground and from techniques of reproduction.

Main reproduction problems: spreading of the paint, poor fixation of paint, too low contrast between the color of the substrate and the color bars.

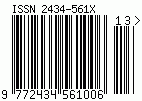

GS1 specification (5.2.1.4.1) - change bar widths for digits 1, 2, 7, 8

For barcodes EAN-8,

EAN-13,

UPC-A,

UPC-E,

ISBN,

ISSN

in GS1 specification we can read:

„For digits 1, 2, 7, 8 the bars and spaces are reduced or enlarged by one-thirteenth of

a module width to provide a uniform distribution of bar width tolerances and thus improve scanning reliability.”

Barcode generators EAN-8, EAN-13, UPC-A, UPC-E, ISBN, ISSN support this option.

Barcode generators EAN-8, EAN-13, UPC-A, UPC-E, ISBN, ISSN support this option.

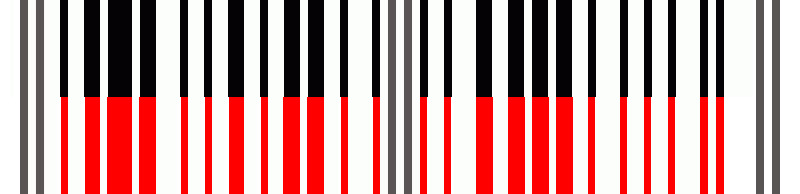

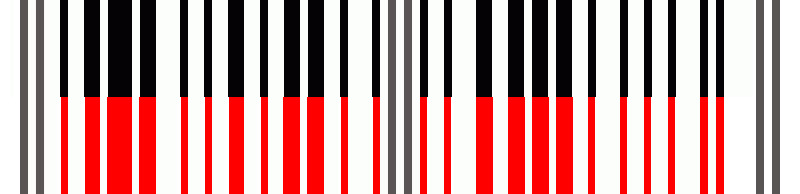

Barcode EAN-13 (1278127812786)

• black colour - barcode generated without change bar widths for digits 1, 2, 7, 8,

• red colour - barcode generated with change bar widths for digits 1, 2, 7, 8.

Bar width reduction

One of the most common problems during reproduction is an increase in the thickness of the bar.

Each of the generators have the capability to reduce the width of the line.

This allows the generation of such a code, which after being printed will have the correct width of the bar.

That increases your chances of reading the code by the reader.

For barcodes EAN-8,

EAN-13,

UPC-A,

UPC-E,

ISBN,

ISSN

nominal bar width is 0.33 mm.

Using the bar width reduction must not lead to a situation where the thinnest bar will be less than 0.13 mm in the printing form.

If this happens, use a higher zoom ratio to (0.33 mm × magnification factor) - REDUCE WIDTH ≥ 0.13 mm.

-

no bar width reduction (BWR = 0)

Generated

After reproduction

-

with bar width reduction (BWR > 0)

Generated

After reproduction

Scale (zoom factor)

For barcodes EAN-8,

EAN-13,

UPC-A,

UPC-E,

ISBN,

ISSN

it is recommended to use Coefficient of magnification in the range of 80% to 200% of the nominal size.

Each of the generators allows you to enter the zoom ratio in this range.

Recommended zoom factors:

Recommended zoom factors:

| Process and material | Min. scale |

|---|---|

| Offset printing | 80% |

| Flexographic printing on paper and foil | 130% |

| Flexographic printing on corrugated board | 160% |

| Screen printing | 120% |

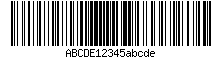

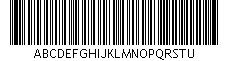

Wide to Narrow bar ratio („wide element” to „narrow element” ratio)

The wide-to-narrow ratio of a barcode is the relationship of narrow elements to wide elements.

Example: ratio 3, set width of „wide element” to 3-times larger than the „narrow element”.

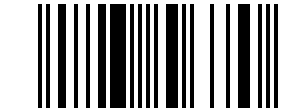

-

Barcode created with ratio 2.5

„narrow element” - width 2px

„wide element” - width 5px

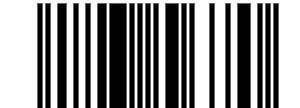

-

Barcode created with ratio 4.0

„narrow element” - width 2px

„wide element” - width 8px

The contrast between the base color and the color of bars

The most frequently used bar code readers are equipped with red light - 630 nm wavelength.

Symbols are correctly read only if the prints with the printed code, lines dimensions, have got right overprint contrast.

Obtaining the contrast is dependent on both the background color and the color bars.

The background should as bright as possible and the lines should be at their darkest.

Background color should be: white, yellow, orange or bright red, and lines: black, blue, green and dark brown.

The accuracy of output devices

When reproducing the barcode accuracy of output devices must be considered.

Inkjet printer running at a resolution of 600 dpi is accurate to 0.0423 mm.

So if we print on the 0.33 mm bar we may receive a dash with a thickness from 0.2961 mm to 0.3384 mm.

An imagesetter, which is used to perform printing forms works usually with a resolution of 2540 dpi, gives the accuracy of 0.01 mm.

In this case, the bar width is between 0.32 mm and 0.34 mm.

Industrial barcode printers

The vast majority of industrial printers has resolution 203.2 dpi (8 dpm).

This means that the printer has a precision of 0.125 mm.

We can print lines, eg: 0.125 mm, 0.250 mm, 0.375 mm (line thickness is a multiple of 0.125 mm).

Industrial printers at higher resolutions are also available:

304.8 dpi (12 dpm), giving an accuracy of 0.0833 mm

or even 609.6 dpi (24 dpm), giving an accuracy of 0.0416 mm.

Most programmers who first encountered an industrial printer were trying to treat it like a regular office printer.

This approach results in poor print quality, as there is no proper easy way to control the printout (barcode parameters) of the generated barcode

when programmers use software like CrystalReport or FastReport or when trying to print to this printer using a driver provided to the system.

By printing in this way we always get better results for office printing than for an industrial printer.

Printing on such a printer boils down to writing a program and sending it to it.

The most popular industrial printer programming languages are: DPL, EPL, ZPL, Basic, J-Script.

Typically, all industrial printers have features that allow you to print codes.

Using these features gives the best results: the code is very clear, readable, and does not cause problems when trying to read by any barcode reader.

Any attempt to print codes otherwise fails (the quality of the printed code is far from expected).

Barcodes generated on this page have been printed and scanned with a barcode reader AS-8000

(except Pharmacode, Postnet, Planet, Royalmail, Code-16k, Code-32), QR, DataMatrix, Aztec, PDF417 and DataBar (RSS) codes will be scanned with

ZXing Decoder Online. Some readers

require proper configuration so that they can read correctly some of the codes: part of the code

is normally disabled, some codes have checksum, but do not need to have one, etc. The creators of the site

have made every effort to ensure the high quality of the generated barcodes. Barcodes generated by the

service are provided on a rule "as it is" without warranty of any kind, when it comes to the quality

and suitability for use. This website is not liable for any damage resulting the use of barcodes that

are generated by this website. Use of this website means unconditional acceptance of the above information.

© 2012-2026 www.free-barcode-generator.net. Any material, information, files, drawings, pictures, etc. available on the website www.free-barcode-generator.net may not be published

and redistributed without permission www.free-barcode-generator.net. This material is limited by copyright and other laws and may not be copied, published and distributed in any form.

All names, trademarks that were used on www.free-barcode-generator.net are the property of their respective owners.

They were only used to help identify the owners of those marks or their products.

They were only used to help identify the owners of those marks or their products.

info(at)free-barcode-generator.net

The above e-mail address is published only for the purpose of contact www.free-barcode-generator.net website users with author

and for the purpose of reporting any improvements and fixes. It is forbidden to use the above e-mail address for marketing purposes.

The above e-mail address is published only for the purpose of contact www.free-barcode-generator.net website users with author

and for the purpose of reporting any improvements and fixes. It is forbidden to use the above e-mail address for marketing purposes.

Your IP address: 216.73.216.36

Active users: 2 646

Date and time: 2026-01-02 01:47:49

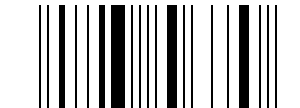

![Code-16K code, encode

1234567890,./;'[]-=!@#$%^&*()_+ Code-16K code, encode

1234567890,./;'[]-=!@#$%^&*()_+](/images/start/code-16k_numeric_special.png)